Factory simulations from UK show off automation

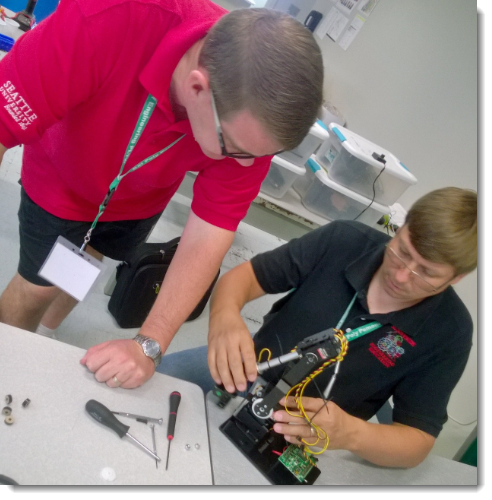

Doesn’t get much better than this! 18 teachers from around the country gathered at the University of Kentucky to learn about CIM for two weeks. They spent two days showing off what they learned by making a factory simulation. The class was broken up into two teams, and both successfully completed their tasks.

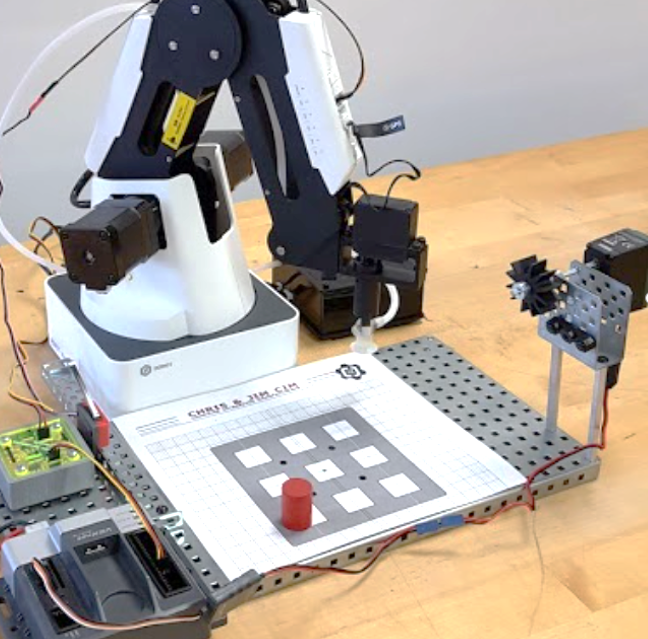

The rules were as follows:

- Each team must have two Lynxmotion robotic arms

- There must be multiple handshakes between pieces of equipment

- There have to be at least three different operations

- The factory must include VEX

- There must be pneumatics or hydraulics involved

The first team built an automated bourbon barrel filling station. It drilled, filled, bunged, transported, stamped and stored barrels.

The second team built a machine that recycled golf balls and turns them into range balls, complete with striping mechanism. Used two Lynxmotion arms, many handshakes, lots of VEX, 3D printed grippers and pneumatics!

1,277 total views, 1 views today