CalPoly Pomona: Factory Smackdown!

The new CIM (Computer Integrated Manufacturing) teachers at CalPoly Pomona’s CTI successfully completed another “Factory Smackdown”. See the videos below!

Concierge Factory:

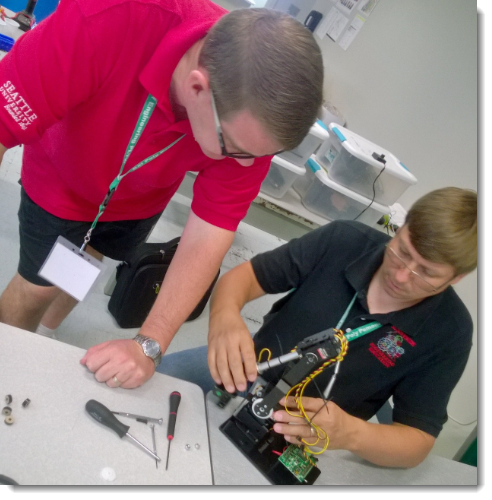

In our factory cell an AGV stops at each of four stations, where a signal is sent to a robotic arm. The arm picks up a product, places it into the package, then sends a signal to the AGV to rotate the pack and move to the next station. Once the package is full, the AGV offloads it onto the shipping dock.

In our factory cell an AGV stops at each of four stations, where a signal is sent to a robotic arm. The arm picks up a product, places it into the package, then sends a signal to the AGV to rotate the pack and move to the next station. Once the package is full, the AGV offloads it onto the shipping dock.

[youtube_sc url=”https://youtu.be/FGtFBXoQGQQ ” width=”800″]

Fruit Sorter:

By using VEX and Lynxmotion we created a fruit sorting factory. The Lynxmotion robots grabbed the fruit from the funnel line, placed the fruit at the color sensor(aka line sensor) then placed the fruit into the correct bin. The AGV then took the fruit away, and the system started all over again.

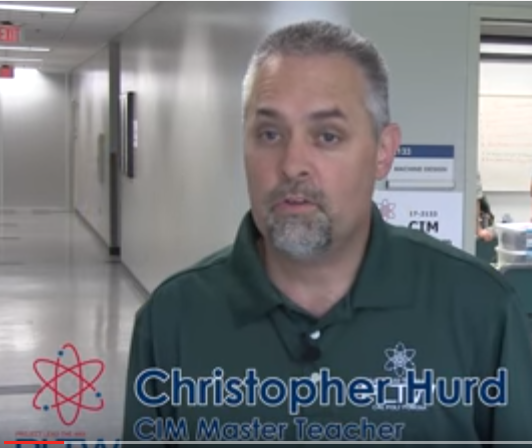

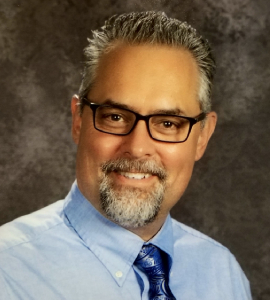

Special Thanks to~ Our Master Teachers Chris Hurd and Moises Gonzalez and our group members: Khris Kading, Martin Velasio, Donnie Whitworth, Rich Mayfield, Candy Drabek, and Gary Potter.

[youtube_sc url=”https://youtu.be/vhZB4rYg5uE ” width=”800″]

Toxic Waste

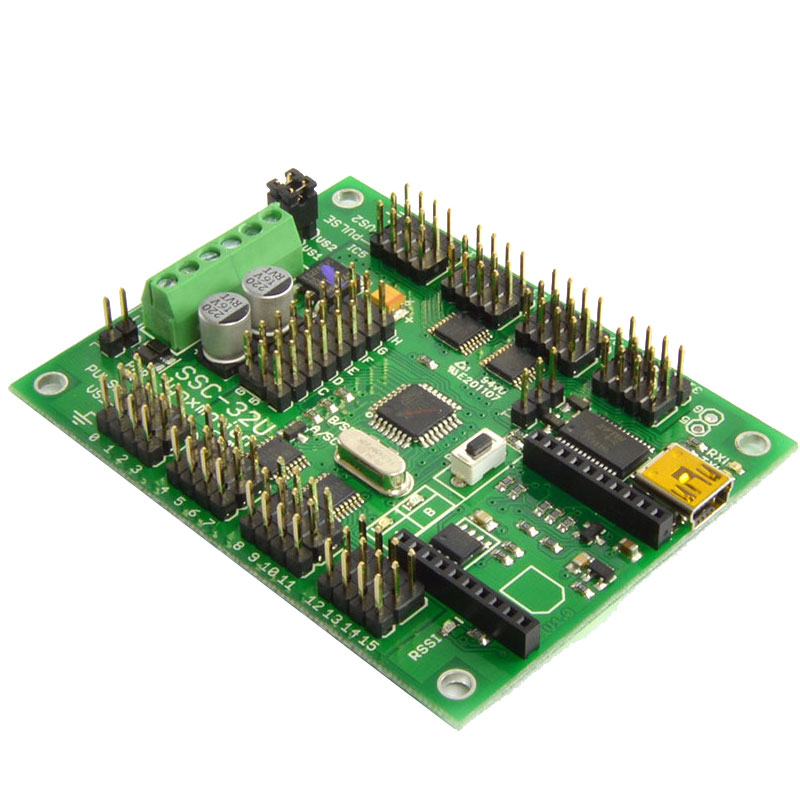

Cal Poly Pomona CIM Core Training, 2016. Team Toxic Hurd takes on the challenge of packaging, containing, sealing and transporting toxic waste, practice golf balls. This factory cell uses two Lynx Robotic Arms and two VEX Cortex. The Lynx arms and the Cortex communicated with each other to signal the ‘handshake’ required to keep all the operations ruining on time. The Lynx arms are controlled with Flowarm, and the Cortex was programmed with RobotC.

[youtube_sc url=”https://youtu.be/gkSNFdzwksU ” width=”800″]

![]()