Intellitek Mill: From Set up to Making Your First Part

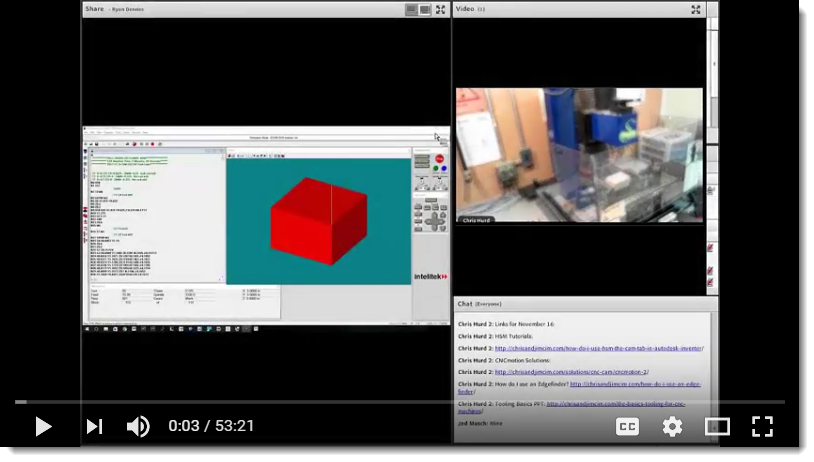

So you have a new small cnc milling machine… what now???? From how to clamp a part to the table to making your first part, this is the video to watch. See the references section below for links to the other info in the video.

[youtube_sc url=”https://youtu.be/4SA1FK_WgXs” width=”900″]

Video Time Stamps:

| 0:24 Vices 0:38 Drill press vice 1:25 Machine vice 2:30 Accuracy of a vice 4:30 Machinist squares 5:25 Strap clamps 8:42 Fixed corner/stock 9:00 Putting your stock in the vice 10:00 Laser cut parallels 10:50 other parallels 11:30 Magnetic parallels 13:00 Finding home 13:55 Finding PRZ 14:00 What’s a tool library? 15:00 What’s PLTW’s tool library |

16:30 What tool can I use to cut wood? 17:30 CNCmotion: entering tools 19:50 Installing a tool in the spindle 20:30 Using the height offset gauge 22:05 testing your tool library 25:48 Setting a reference height 30:30 Preventing oxidation 33:30 Finding PRZ 34:10 Using an edge finder (video) 37:01 ILAR method 38:20 Match the tool in the machine to the one in the software. 39:59 Changing stock size CNCbase/motion 40:30 Verify the part 42:30 Run the part 49:30 Safe position |

How do I use HSM to make parts in Inventor: http://chrisandjimcim.com/how-do-i-use-hsm-the-cam-tab-in-autodesk-inventor/

CNCmotion Solutions (answers to common questions when using CNCmotion): http://chrisandjimcim.com/solutions/cnc-cam/cncmotion-2/

How do I use an Edgefinder? http://chrisandjimcim.com/how-do-i-use-an-edge-finder/

[youtube_sc url=”https://youtu.be/f0od-cp_9dg”]

Tooling Basics PPT can be found on this site here: http://chrisandjimcim.com/the-basics-tooling-for-cnc-machines/

Step Clamps: http://www.mscdirect.com/product/details/04804571

Toolmaker’s Vise: http://www.mscdirect.com/product/details/42052761

Drill Press Vise: http://www.mscdirect.com/product/details/70037882

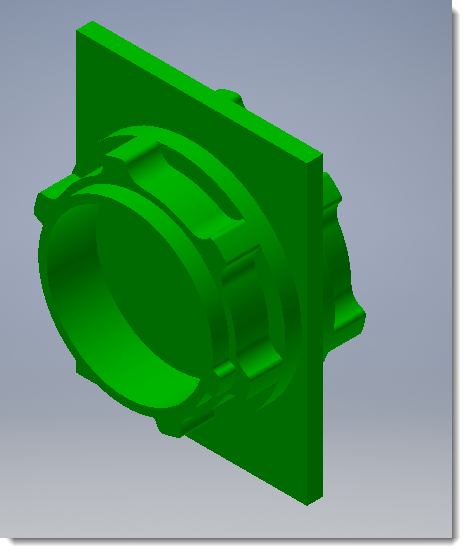

Parallel Clamp (Use with a neodymium magnet, you can buy them at Home Depot) https://www.dropbox.com/s/efp2crsef3pqzp5/ParallelHolder.ipt?dl=0

Cyclone for your Shop Vac: https://www.amazon.com/Oneida-Molded-Dust-Deputy-Cyclone/dp/B002JP315K/ref=pd_lpo_469_bs_tr_t_2?_encoding=UTF8&psc=1&refRID=T213Z6E63NSMVXKTNYN5

![]()