CalPoly Pomona: Factory Smackdown!

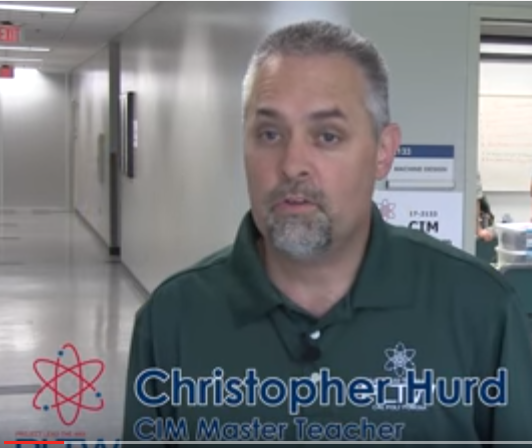

The new CIM (Computer Integrated Manufacturing) teachers at CalPoly Pomona’s CTI successfully completed another “Factory Smackdown”. See the videos below!

Concierge Factory:

In our factory cell an AGV stops at each of four stations, where a signal is sent to a robotic arm. The...