Tag: cad

Youtube PlaylistSnowflake Challenge

Introduction:

You have been approached by your high school’s tech club to help them design a snowflake style ornament for their annual fundraiser. This year they would like to offer an ornament that has been laser cut. They have a few requests...

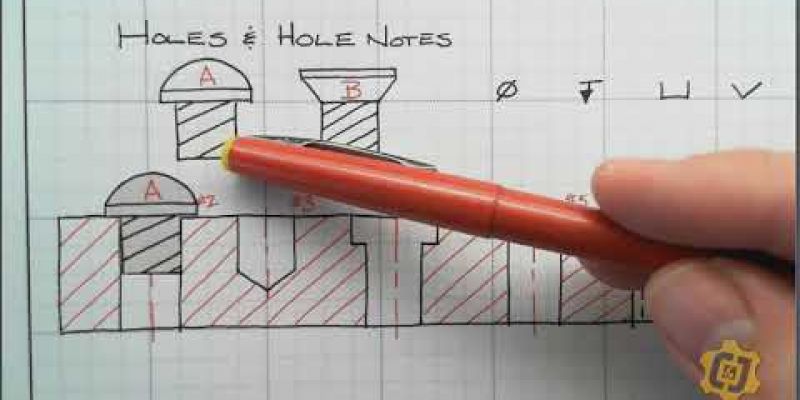

Hole Notes and Hole Types

Question:

Geez… there’s lots of different types of holes…. how do I know the difference when reading a drawing?

Answer:

Once again… Jim to the rescue with a LOT of information about holes.

Going Beyond: Hole Notes

Answer the questions below by copying and...

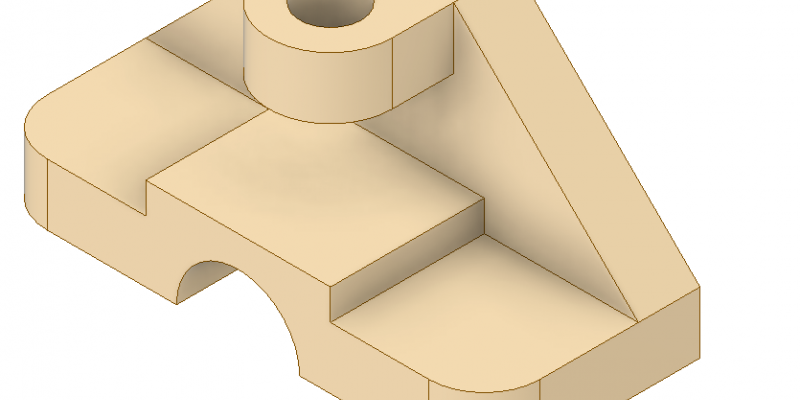

Advanced CAD Modeling & Mfg Math Activity

Worksheet with DimensionsElectronic Hand-in Document

In this activity, students can download the worksheet with the dimensions and directions, and use them to build the METRIC models in your favorite 3D modeling software. NOTE: Worksheet with Dimensions Drawings updated 4/30/2020… Thanks...

Basic Part Creation Using Autodesk Fusion 360

Download the Worksheet Download Hand-In

Student Notes: Download the Worksheet, dimension the parts using the given scale, then make them in your 3D modeling software! Here is a project to help you and your students get acquainted with Autodesk Fusion 360. There are eleven parts to make, and...

2015-16 PDP #5: The CAD/CAM Process

on Wednesday, 18 November 2015.

THE 5TH INSTALLMENT OF AN ONGOING SERIES ON HIGHLIGHTS OF THE PLTW CIM CURICULUM

The fifth PDP session for the 2015-16 school year was held last night. In this one, Chris talks about the CAD/CAM Process. No matter what you use for CAD software, or CAM software the...

How do I use Inventor to make The Flange?

Question:

How do I use Inventor to make The Flange?

Answer:

See the video below for one way to do it. It walks you through all the steps from hole cycles to profiles, to roughing operations.

The video below does not have any sound track.

[youtube_sc url=”https://youtu.be/SBIlHm4jAt8″ width=”800″]

...

CAD Practice

on Wednesday, 07 January 2015.

HOW TO MAKE THE AUTOMOBLOX WINDSHIELD

Found a great video that shows, and explains the basics of how to build the automoblox windshield.

Thanks to Mr. McCarroll from Round Rock High School for providing this video from his youtube channel.

Tags: