What vocabulary is necessary to be successful in CIM, wether as a student or teacher; in the classroom or at CTI?

Solution:

Great question, as many studies have shown that a strength in vocabulary leads to success in ALL areas, and this includes CIM and manufacturing education.

![]() Click HERE to get the list as a PDf download.

Click HERE to get the list as a PDf download.

Below is a list to get started.

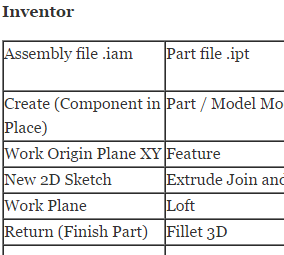

Inventor

| Assembly file .iam | Part file .ipt | Design 2D Sketch Mode | Finish Sketch |

| Create (Component in Place) | Part / Model Mode | Line | Constraints |

| Work Origin Plane XY | Feature | 2-Point Rectangle | Coincident Constraint |

| New 2D Sketch | Extrude Join and Cut | 3 Point Arc | Equal Constraint |

| Work Plane | Loft | Center Point Circle | Tangent Constraint |

| Return (Finish Part) | Fillet 3D | Construction Line | Slice Graphics |

| Offset (Loop & No Loop) | Derive Part | ||

| Fillet 2D |

EdgeCAM

| Design Mode | Offset | Manufacture Mode | % Step Over |

| Auto Stock | Line | Post | Cut Increment |

| CPL/PRZ | Text | ToolStore | Boundary |

| Create CPL | Transform/Translate | Roughing Operation | Lead Radius |

| Select CPL | Distance / Measure | Speed (Spindle) | Use Current Tool |

| Feature Finder | Feed Rate | Profiling Operation | |

| Boss (Island) | Plunge Feed Rate | Surface Operation | |

| Climb | Hole Operation | ||

| Hole | Conventional | Slot Cycle | |

| Profile Loop (Feature Finder) | Optimized | Parallel Lace | |

| Mill Feature (Feature Finder) | Clearance | Constant Cusp | |

| Hole (Feature Finder) | Depth | Z Level Finishing | |

| Geometry from Loops | Level | Cycle Time | |

| Comparison | |||

| Simulation | |||

CNC

| Preparatory Code (G) | Miscellaneous Code (M) | Speed Rate | Origin / PRZ / CPL |

| G90 Absolute | M02 End Program | Feed Rate | Datum |

| G91 Relative / Incremental | M03 Spindle On (Needs S) | Plunge Rate | Modal |

| G00 Rapid Traverse | M05 Spindle Off | Block | Plunge |

| G01 Straight Line Interpol | M06 Tool Change | Address Character | Retract |

| G02 Cir Interpolation CW | M30 Program End and Reset | Parameter | Safe Position / Clearance |

| G03 Cir Interpolation CCW | M08/M09 Accessory 1 on/off | Word | Jig |

| G04 Dwell (Needs F) | M10/M11 Accessory 2 on/off | X Axis | Fixture |

| G05 Pause | Y Axis | Numerical Control (NC) | |

| G20 Inch Mode | F = Feed Rate or Time | Z Axis | Pneumatic Vise |

| G21 Millimeter Mode | Chip Load / Tool Feed | XY and IJ and R | Machinist Vise |

| Comment | Cutting Speed-Surface ft/min | Ball Screw | Strap and Step Clamp |

| Acme Screw | |||

| Tool Center Point (TCP) | Tool Cutter Compensation | Tool Height Offset |

CNC Motion

| Home | Setup Library | Verify Setting | Operator Control |

| Verify | Setup Tool Wizard | Stock/Vise | Single Step |

| Run / Cycle Start / Simulate | Select Tool | Feed Override | End Mill |

| Pause | Set Position | Speed Override | Ball End Mill |

| Stop | Run Setting | Jog Control | Bull End Mill |

| Estimate Run Time | Arc Centers Incremental | Step Jog | Taper End Mill |

| Jog Control | Go to Position | Continuous Jog | Non-Center Cutting |

| Work Space | Send Tool to Corner | Soft Limits | Center Cutting |

Robot C

| Open Sample Program | Digital Sensor | Natural Language | Compile |

| Pseudo Code | Touch Sensor | Task main | Debugger |

| Pragma | Quadrature Encoder | If-Else Loops | Firmware (Master / RobotC) |

| Motors and Sensors Setup | Sonar / Ultrasonic | While Loops | Platform Type |

| Motor | Analog Sensor | Variables | |

| Motor 269 | Potentiometer | Functions | |

| Motor 393 | Light Sensor / Photo Cell | Void | |

| Flashlight / LED | Line Follower / Infrared | Open and Closed Loop | |

| Motor Controller | LED | Normally Open | |

| Servo | DigitalPort | Normally Closed | |

| MotorPort | Until | Feedback | |

| Motor Backlash | Wait |

RoboCELL

| ER4U | Axis Control | Program Flow | Inputs and Outputs |

| Peripheral | Open Gripper | Wait | If Input |

| Feeder | Close Gripper | Jump | Turn on Output |

| PLM1000 | Go Linear | Remark | Turn off Output |

| Controller Setup | Go Circular | Set Variable to Computation | Joints Movement |

| If Jump | XYZ Movement | ||

| Record Position | Work Envelope | Label | |

| Teach Position | Payload | Follow Me Camera | |

| Roll | Reset Workcell | Servo Motor | Run Single Line |

| Pitch | Dialog Bars | Stepper Motor | |

| Get Position | Home | Encoder | |

| Send Robot to Object | Degrees of Freedom |

Elements of Power

| Ampere | Power | Watt | |

| Electrical Current (I) | Revolutions per Min (RPM) | Work | |

| Force | Servo Motor | ||

| Horsepower (HP) | Stepper Motor | ||

| Hydraulic | Torque | ||

| Joule | Velocity | ||

| Pounds Per Square Inch (PSI) | Viscosity | ||

| Pneumatic | Voltage (V) |

Flowbotics Studio

| Handshaking | Calibration | Joint Movement | |

| End Effector | Work Envelope | AL5D | XYZ Movement |

| Input | Servo Motor | Record | Spare Servo |

| Output | Payload | Pause | Accuracy |

| Optoisolator | Schematic | Copy | Reliability |

| Relay | Loop | Delete | Repeatability |

| Resistor | Step | Global Speed | |

| Breadboard | Sequence | SSC-32 |

Misc

| AGV | ASRS | Automation | CAD |

| CAM | CIM | Dependent Variable | Independent Variable |

| JIT | Kaizen | Six Sigma | Variable |

| Fixed Cost | Value-Added | Non-Value Added (NVA) | Overhead |

| Profit | Raw Material | Variable Cost | Durability |

| Design Flaw | Quality Control | Ethics / Morality | Defective |

| FDM | Stereolithography | Laser Sintering | 3D Printing |

| LOM | Prototype | Subtractive Process | Additive Process |

| Post Processing | Build Time | Exhaustible Resource | Renewable Resource |

| Inventory Control | PLC | Microcontroller | FMS |

| Process Design Chart | Workcell | ||

| Flow Process Chart | |||

| Operation | Delay | Transportation | Storage |

| Inspection |