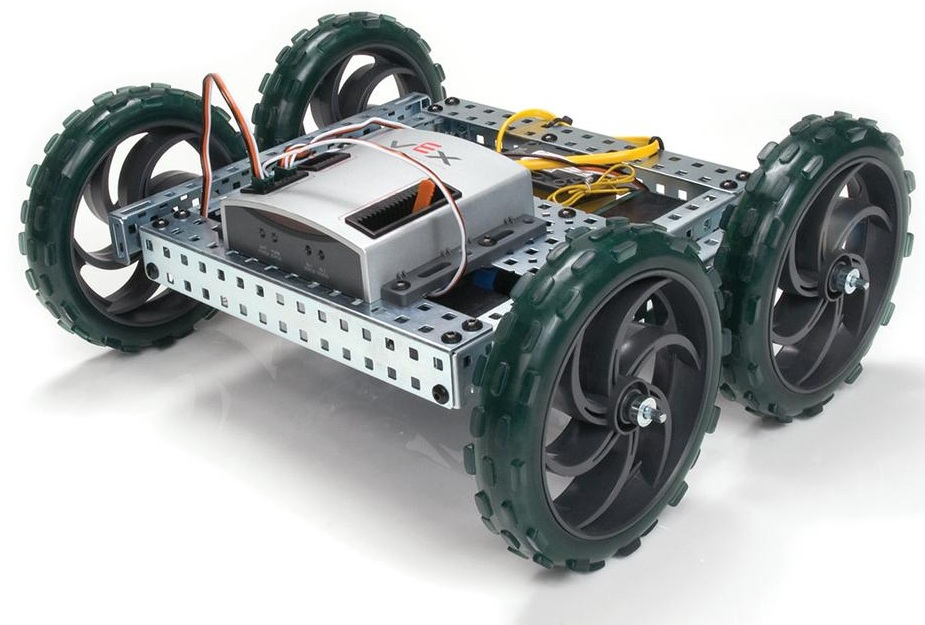

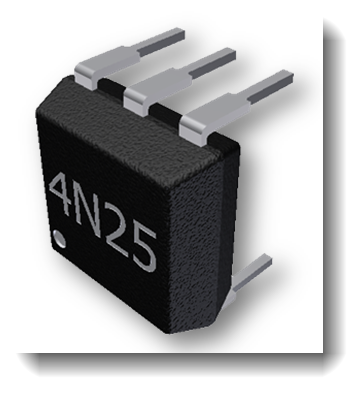

Is there an easier or faster way to make the testbed? The VEX take a very long time to work with, and there must be an easier way to do it.

Solution:

Well, there is; if you have a laser and access to some acrylic. Jim has designed a VEX testbed that can be made out of a 1/8″ or 1/4″ thick piece of acrylic, less than 8″ x 10″.

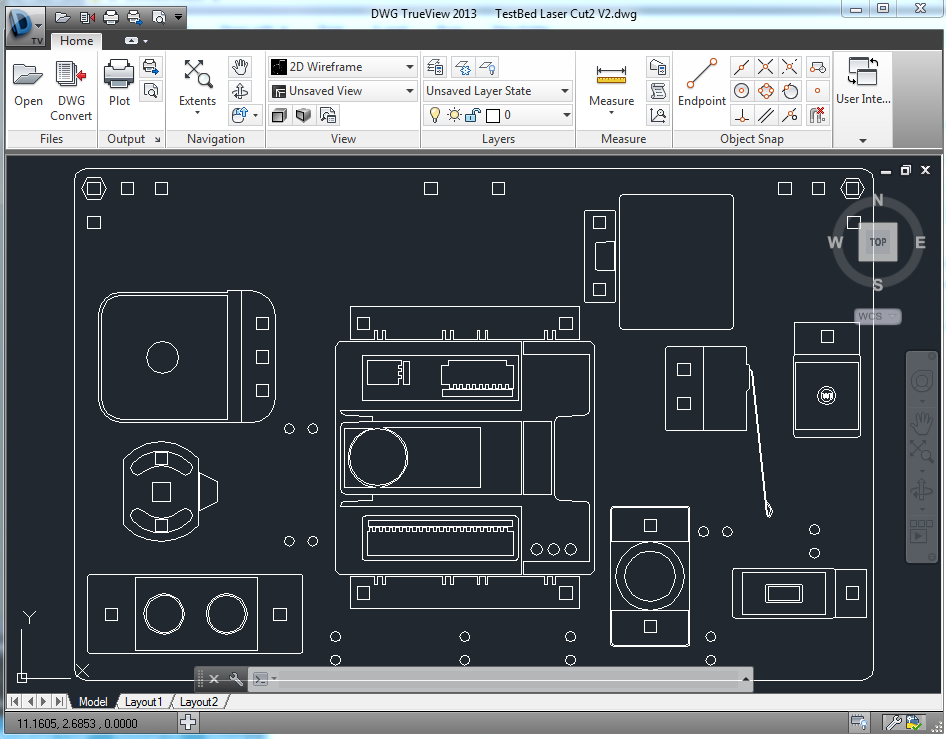

Just download the dwg file below and prepare it for your laser as you would any other file!

This is great for many reasons:

- The only holes machined are the holes for the components, no more counting holes.

- You can engrave the image right on the board so the students know where everything goes.

- You could engrave the names of the compenents too so that it builds component recognition.

- Cuts down on time to build them.

- Makes them smaller and easier to store.

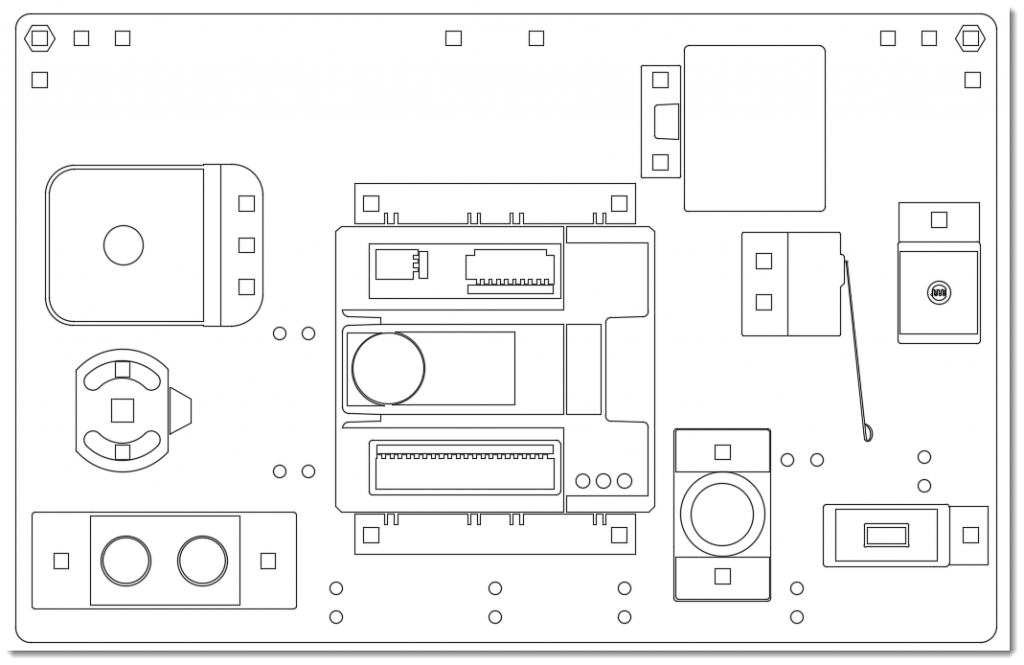

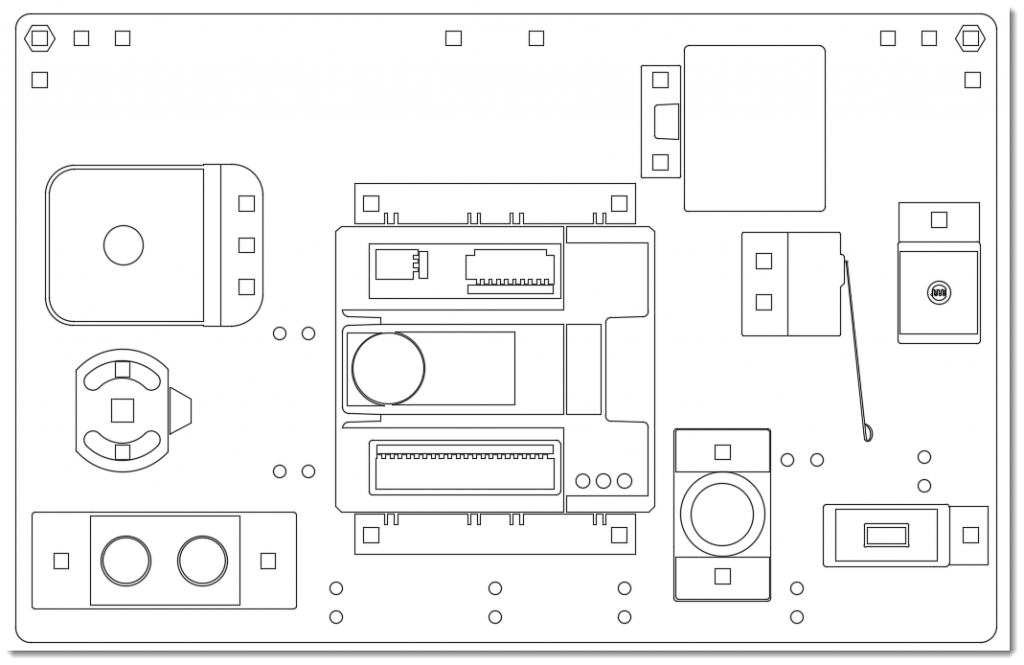

Here is a picture of the file: