Tag: lynx

So which robots should I use in my classroom? Dobots? Lynxmotion? Rotrics? Fanuc? Great question! Jim and I use Dobot’s exclusively in our classrooms for many reasons. One of which is because we wrote the curriculum for them: Teach and Playback and Blockly. Below we have come up with some justification...

The Lynxmotion AL5D V2: Putting it all together

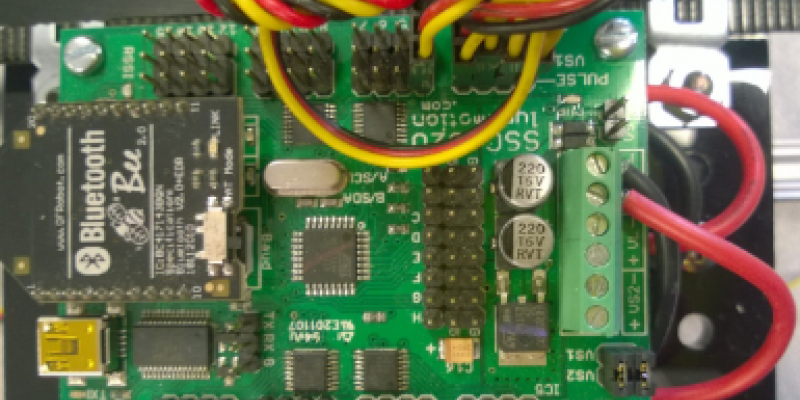

So you have new Lynxmotion robots for your classroom, so now you have to build and wire them. I’ve put together 4 videos to help you assemble and wire them. This is not meant to replace the manual, but rather to supplement it. You can find the manual here: PLTW-AL5D-Guide-11. Lots of new...

Centering Servos

Question:

How do you center the servos when you build your lynxmotion AL5D?

Answer:

Best way is to NOT turn the servos; like that’ll happen! There is a whole section in the new manual that can help you teach how servos work, so check the manual too! You can find it here: PLTW-AL5D-Guide-11. One...

Wiring the Power for Lynx AL5D

Question:

How do you wire the AL5D Lynxmotion robot arm for power?

Answer:

You really have to make sure that you do this right, or you will damage the SSC-32U and/or the power supply, and it will not work. So, start by reading the manual; you can find it Here: PLTW-AL5D-Guide-11. Also, see the video...

How do you wire the Lynxmotion AL5D?

Question:

How do you wire the AL5D Lynxmotion robot arm? That’s a lot of wires!

Answer:

Well, start by reading the manual; you can find it Here: PLTW-AL5D-Guide-11. Also, see the video below.

[youtube_sc url=”https://youtu.be/J8EE-z8kouI” width=”800″]

Gaylord box of...

Tips & Tricks for Building a Lynxmotion AL5D Robot Arm

Question:

I heard building the AL5D was really hard. Do you have any tips or tricks for building it?

Answer:

Of course we have tips and tricks! Best one yet? Read the new manual; you can find it Here: PLTW-AL5D-Guide-11. They just spent a lot of time rewriting the manual, and added a lot of our suggestions...

What else do we need to teach CIM?

Question:

What else do we need to really teach CIM? Are there any “extras” that you recommend?

Answer:

We get this question weekly. So here’s what we are going to do. Give you a preview to a Google doc that is live so we can update it on the fly. You will see it right below this...

NEW! Lynxmotion AL5D PLTW Guide

Question:

The guide for building the Lynxmotion AL5D robot is not easy to follow. Do you have any suggestions for building the robot?

Answer:

Of course we do! #1: Robotshop & Lynxmotion put out a brand new guide that can be found HERE. The new guide is very easy to follow with great step by step...

CalPoly Pomona: Factory Smackdown!

The new CIM (Computer Integrated Manufacturing) teachers at CalPoly Pomona’s CTI successfully completed another “Factory Smackdown”. See the videos below!

Concierge Factory:

In our factory cell an AGV stops at each of four stations, where a signal is sent to a robotic arm. The...