Brief History & Explanation of CNC & G-Code

Download the worksheet hereEither download the word document above, and type the answers in and hand in to your instructor, or follow the directions below.

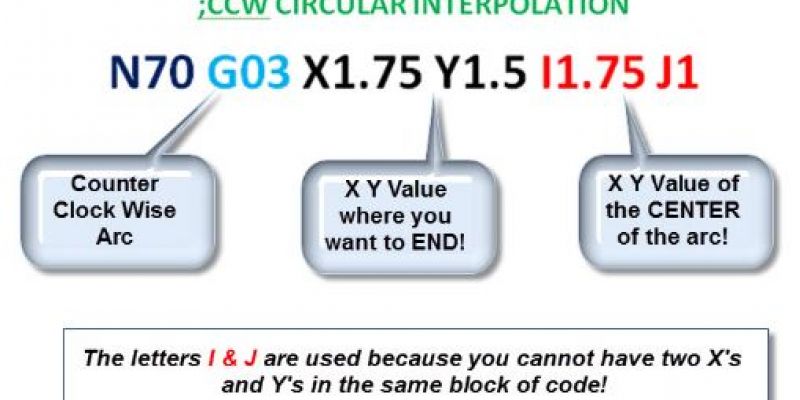

If you look it up the definition will be something like this: G–code is a language in which people tell computerized machine tools...