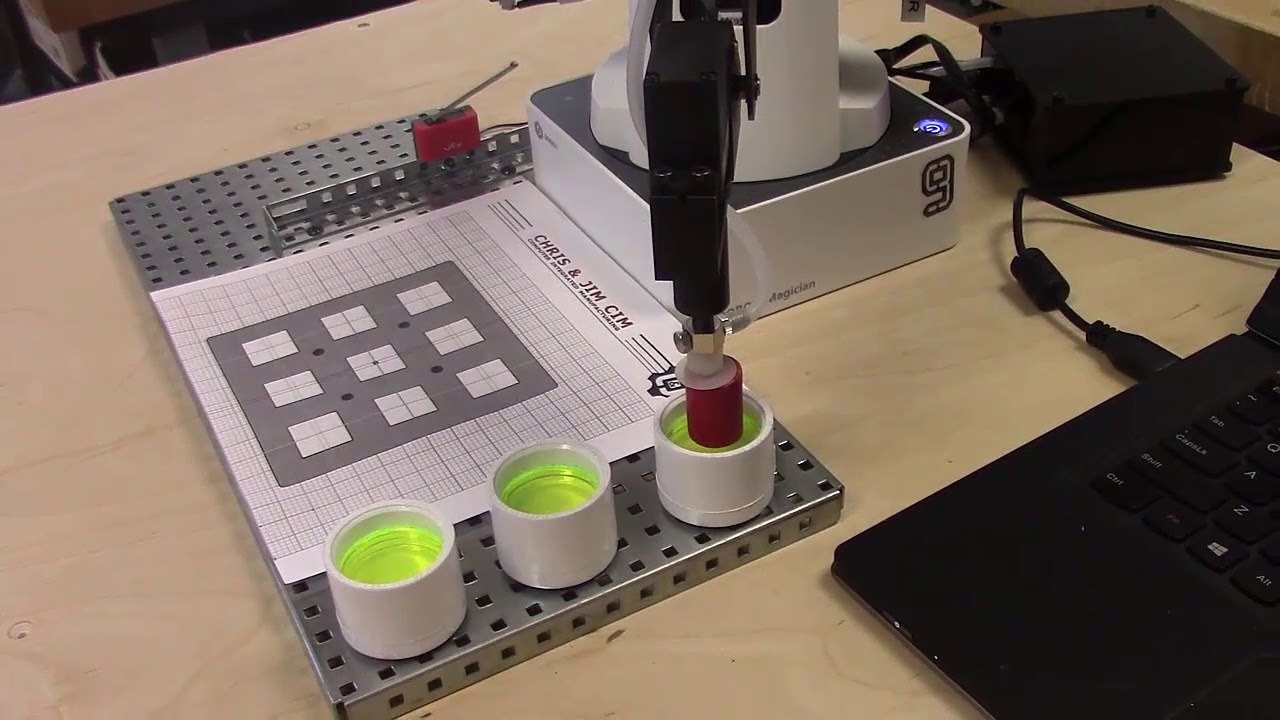

Dipping with the Dobot Magician

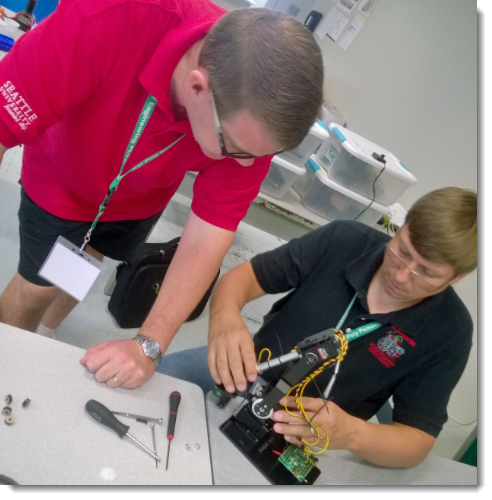

Pick and place and moving things around are staples of industrial robots. Another reason to use robots in industry and automation is because of danger to humans. Robots can work in environments that are adverse to humans; especially toxic and/or adverse environments.

Sometimes the best way to pick...