Tag: mfg

There are many myths about manufacturing held by high school students and adults alike across the US, and right here at home in our high schools. How can high school students make choices about careers in manufacturing if they don’t even know what it is? Here are some of the myths your students...

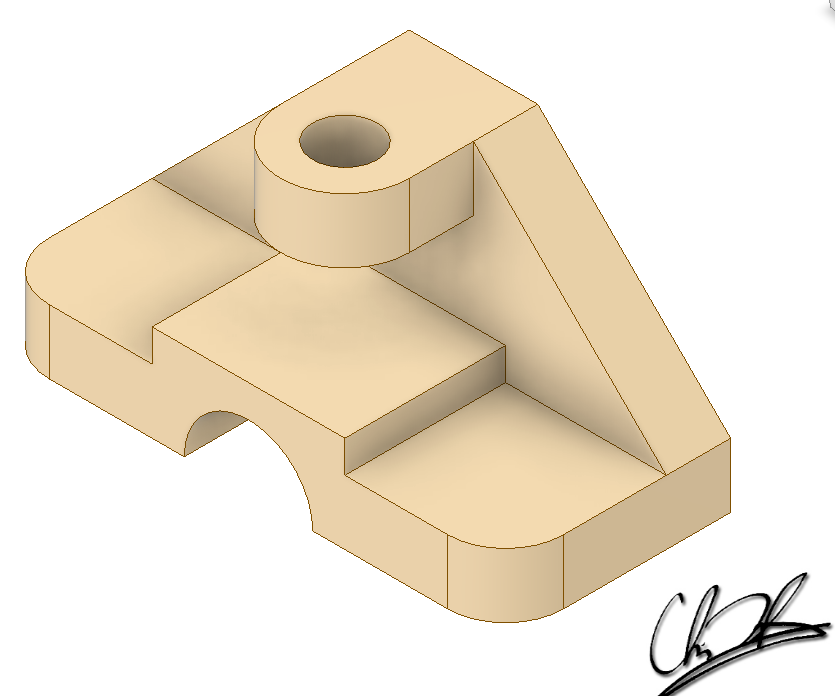

Advanced CAD Modeling & Mfg Math Activity

Worksheet with DimensionsElectronic Hand-in Document

In this activity, students can download the worksheet with the dimensions and directions, and use them to build the METRIC models in your favorite 3D modeling software. NOTE: Worksheet with Dimensions Drawings updated 4/30/2020… Thanks...

MANUFACTURING PROCESS RESEARCH PROJECT: Brochure

Question:

Having students write a paper or do a ppt project for manufacturing processes is boring! Do you have a better idea?

DOWNLOAD: 2017-mfg-research-project

Solution:

Sure do! How about a manufacturing process brochure? This way students have to do a bit of research, (1 to 2 days) on...

01 T&P Robot Axis & Movement

Download Activity

Download Blank Field Template

Jointed arm robots are useful for many different tasks because of its range of motion and degrees of freedom. In this activity you will learn how to move a robotic arm in many different ways and write a program to make the robot write the word...

0.5 Presentation-Introduction to Robotics

Download Here

This is a presentation that can be used as the perfect introduction into the types of robots used in industry today and how it is applied with your classroom robot.

Video coming soon

3,037 total views

Robots vs. Humans: Are Robots Killing Tesla?

Robots vs. Humans; an age old dilemma in mfg. Are you taking CIM? Where do you stand? The robot in this photo is very similar to the one we have in class.

The robots are killing Tesla.

In a rare win for humans over robots in the battle for labor efficiency, Wall Street analysts have laid down a compelling...

How do you use outputs on a Dobot Magician?

Question:

How do you use outputs on a Dobot Magician to do something?

Answer:

How about a grinding operation? See below for the basics. A full blown tutorial will be coming soon!

A Grinding Operation with the Dobot and a Continuous Rotation Servo

This robot is the smoothest, speediest, most accurate...

CIM Material Processes

Your students really need to know how things are made in industry, so below are some resources to help you get started with the learning process. My students became an “expert” in one particular field, picked a topic, and made a brochure about a specific manufacturing process....

Manufacturing in Victoria BC: Straitline Components

Back in 2014 PLTW sent me to Victoria, British Columbia to be an “Educational Consultant” to a production company that was making videos on how things were made in a high tech bike parts manufacturing facility. the name of the company is Straitline, and they were gracious enough to allow...