Tag: machine

Inventor Files ZIP 2D CAM e-Hand-InGDF Flange e-Hand-In 3D CAM e-Hand-In

Using Autodesk Inventor, and Fusion 360 to do CAM (Computer Aided Manufacturing) is getting easier and easier. In these updated videos Jim shows us how to use adaptive milling strategies to quickly and easily remove material...

Tormach PathPilot- Conversational Milling Tutorials

Tormach’s Pathpilot Software contains an awesome feature called Conversational Milling which allows you to create G & M Code for simple or repetitive geometry without any 3D models or CAM. Imagine that… Think of the time you can save! We know there are a few tabs missing, but they...

Intelitek Benchmill Basics

In this series of short videos, learn the basics of how to setup your Intelitek Benchmill 6000 in your classroom. Everything from wiring it, connecting it to your computer, installing tools & vices, and everything in between. Short descriptions of each video below.

« Prev1 / 1Next »1...

How to hold material in the xsTECH

What’s the best way to hold _____________ in my xsTECH router? From strap clamps to double sided tape, we have it all! Learn how to hold everything including circuit boards, flat stock, and blocks in this video.

Can you believe that you can use strap clamps, sticky tape, and all kinds...

Will a vice fit in an xsTECH?

Answer:

That’s a fair question. When trying to come up with an aswer though, you’ll have to do a bit of research, as it will depend on what you’re machining. Also, there are many different one’s out there.

Luckily Jim did some research for us… maybe this video...

Make Cool S*** TV: Youtube Series

This is an interesting “TV show” on YouTube that highlights a different manufacturer in each episode. The first episode is about a company called “Made In America Manufacturing” which is a small machine shop that makes hard to make parts out of hard to work materials like...

Caz HS Tech Labs Gets a Faro 3D Laser Scanner

Cazenovia students will be able to utilize a Coordinate Measurement Machine in the near future. This device is used for measuring the physical geometrical characteristics of an object and is manually controlled. It is a 7 degree of freedom arm with a laser end effector that you could use to scan objects....

A CNC machine for $4000? Really?

Thanks Ryan Dennes! He sent me an email outlining a new CNC machine that will cut everything up to and including aluminum, for only $4000. The post for it is already baked right into HSM too, so you should be able to send code for it right out of Inventor! It’s called the Pocket NC.

I am NOT...

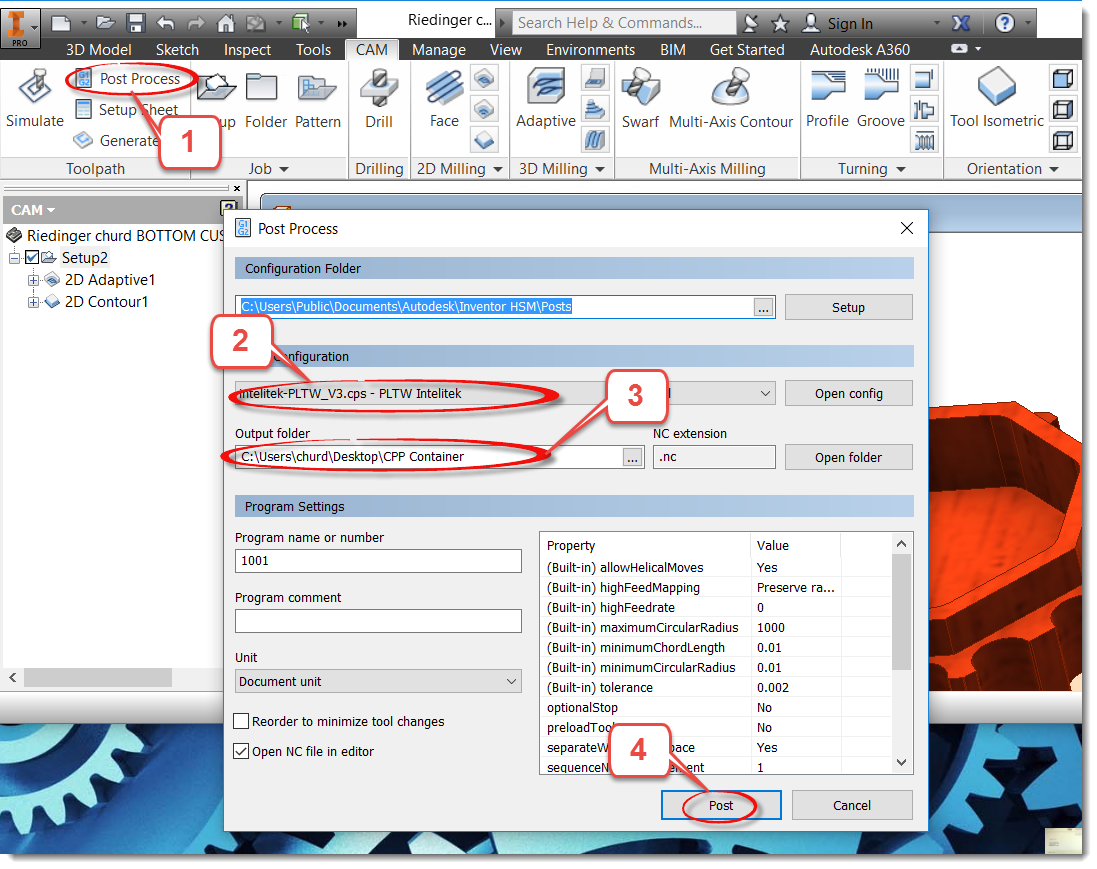

How do I get G&M Code Using Inventor HSM?

Question:

How do I get G&M code from Inventor HSM to make my actual part on the milling machine?

Answer:

post-code-with-hsm

It’s really gotten very easy to do with HSM. Follow the directions below, and you should be all set! Be sure to download the PLTW tool library, and watch video...

- 1

- 2