Tag: cnc

Question:

How are intricate plastic parts made?

Answer:

There are many ways to make plastic parts, but the only way to mass-produce quality parts is by injection molding. At first it may seem like this is a simple process, but in fact it is not — designing the case and all the tooling is...

How Do I Paste G-Code into Tormach

Question:

Can students simply paste the g-code that they have written by hand into the Tormach and run it without having to edit the g-code? For example… if they are doing the Yo-Yo Project?

Answer:

Download the answer as a handout

The Tormach machines need a little more code (closer...

Brief History & Explanation of CNC & G-Code

Download the worksheet hereEither download the word document above, and type the answers in and hand in to your instructor, or follow the directions below.

If you look it up the definition will be something like this: G–code is a language in which people tell computerized machine tools...

Project Idea: CNC Nameplate

Download the Activity

In this project you will be able to take everything you’ve learned about Conversational Machining in PathPilot and put it together in one project to make a name plate. Go to our Conversational tutorials to learn the basics if each step of this project.

The material...

Mounting Stock in a Manual Vice

Question:

How do you mount a piece of stock in a manual vice in your milling machine?

Answer:

CIM Master Teacher Matt Baehr explains how to mount a piece of material in your manual vice and why he does it the way he does. This will apply to all other milling machines as well. See the short...

Intelitek Benchmill Basics

In this series of short videos, learn the basics of how to setup your Intelitek Benchmill 6000 in your classroom. Everything from wiring it, connecting it to your computer, installing tools & vices, and everything in between. Short descriptions of each video below.

« Prev1 / 1Next »1...

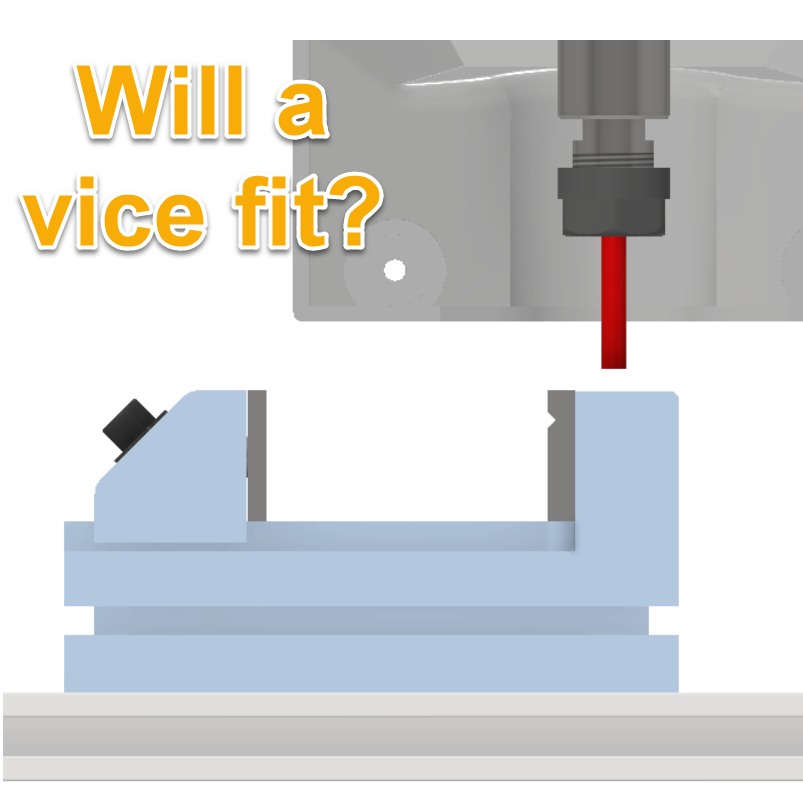

Will a vice fit in an xsTECH?

Answer:

That’s a fair question. When trying to come up with an aswer though, you’ll have to do a bit of research, as it will depend on what you’re machining. Also, there are many different one’s out there.

Luckily Jim did some research for us… maybe this video...

Make Cool S*** TV: Youtube Series

This is an interesting “TV show” on YouTube that highlights a different manufacturer in each episode. The first episode is about a company called “Made In America Manufacturing” which is a small machine shop that makes hard to make parts out of hard to work materials like...

CNC Container Process 2018

Question:

I don’t understand how to make the CNC container project… can you elaborate?

Solution:

There are lots of ways to do it, and a search of this site will give you many, but the steps outlined below is the easiest way to get started. want this is a PDF? Click HERE.

2,346 total...