How to change ramping in HSM

Question:

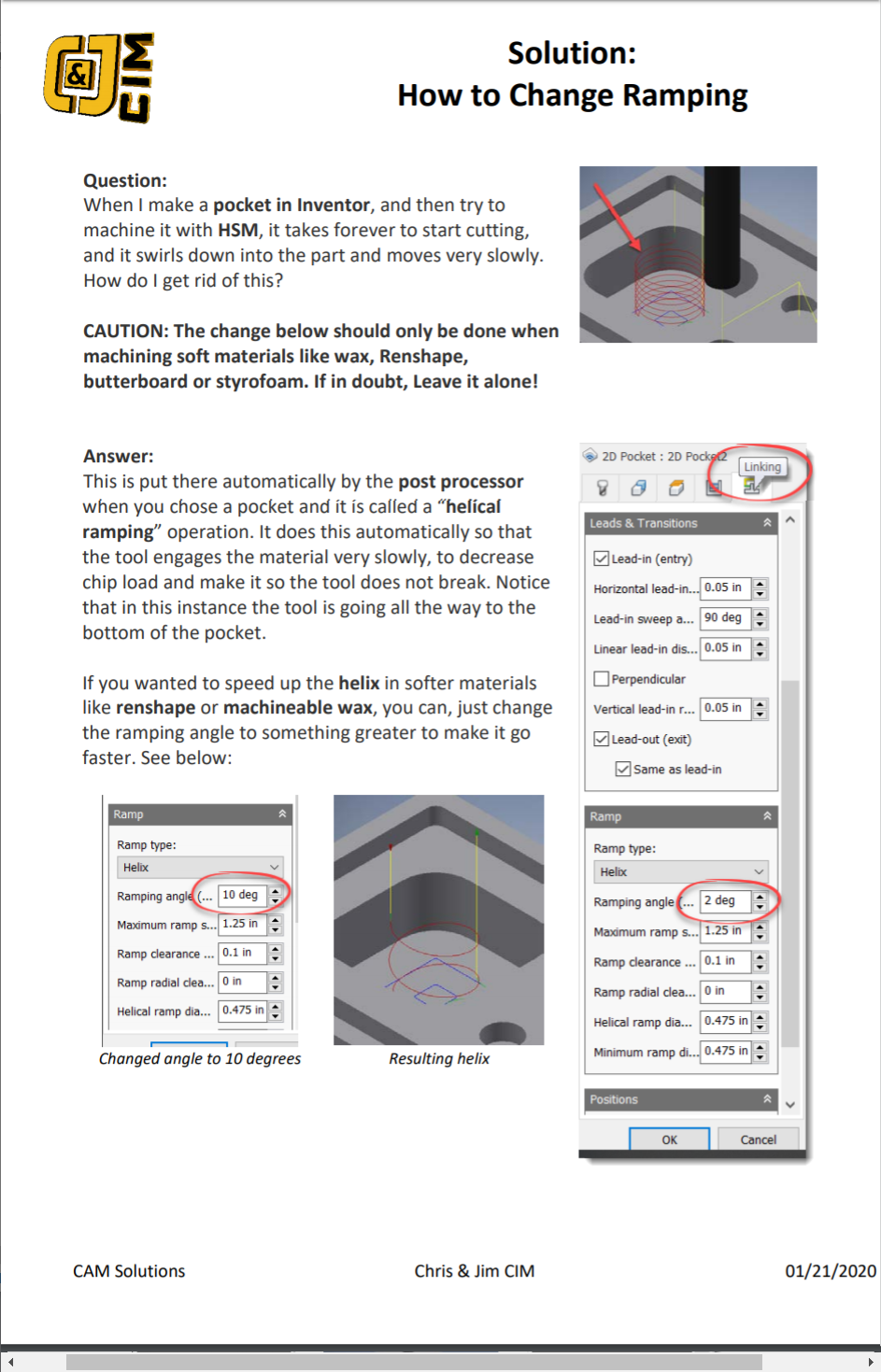

When I make a pocket in Inventor, and then try to machine it with HSM, it takes forever to start cutting, and it swirls down into the part and moves very slowly. How do I get rid of this?

Thanks for the question Marianne!

Solution:

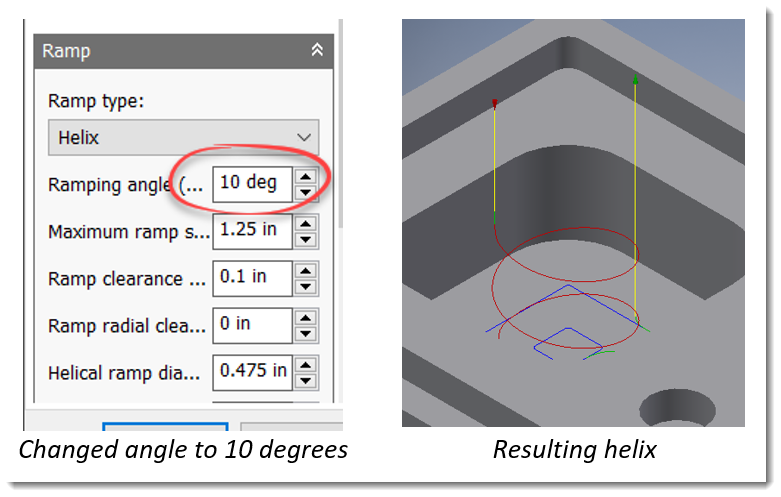

CAUTION: The change below should only be done when machining soft materials like wax, Renshape, butterboard or styrofoam. If in doubt, Leave it alone!

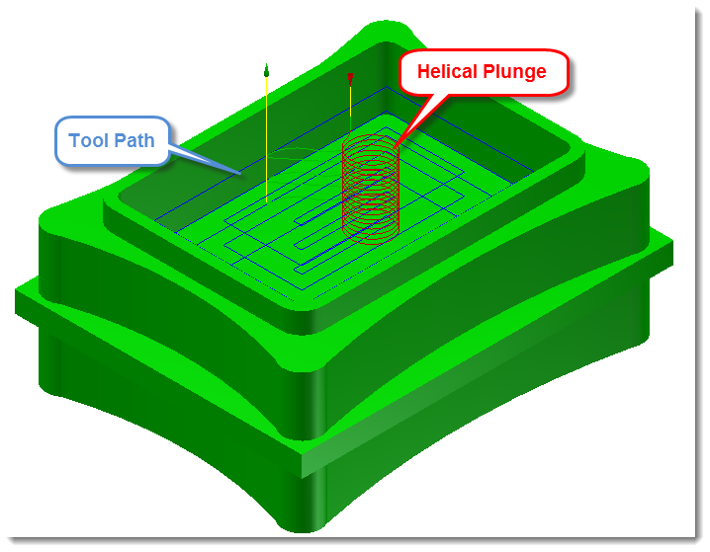

This is put there automatically by the post processor when you chose a pocket and it is called a “helical ramping” operation. It does this automatically so that the tool engages the material very slowly, to decrease chip load and make it so the tool does not break. Notice that in this instance the tool is going all the way to the bottom of the pocket.

To change this in the pocketing operation, edit the operation, choose the linking tab, and scroll down to the ramp menu. If you wanted to speed up the helix in softer materials like renshape or machineable wax, you can just change the ramping angle to something greater to make it go faster. See below:

1,416 total views, 2 views today