Brief History & Explanation of CNC & G-Code

Download the worksheet here Download the worksheet here |

If you look it up the definition will be something like this: G–code is a language in which people tell computerized machine tools how to make something. If you are interested in cnc machining, Free CNC Training Courses are usually offered online. Read more below to learn more about CNC.

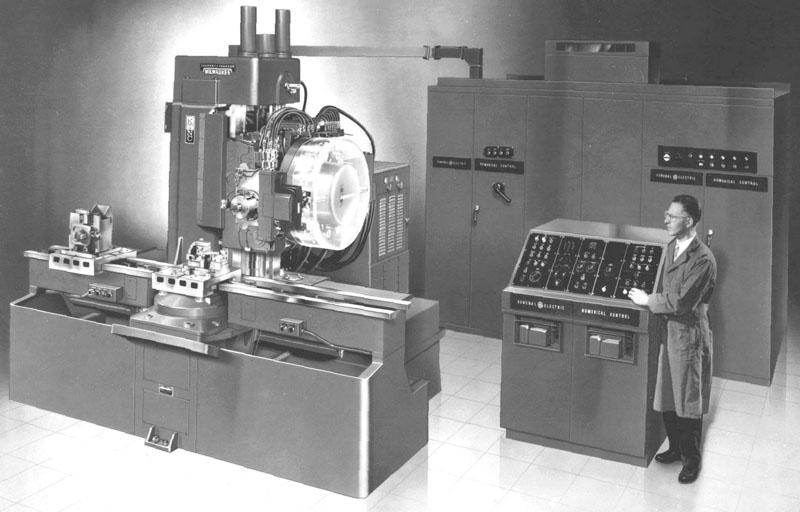

Step 1: A Little CNC History: Read an article and answer the questions

Standard G–code was originally used in the MIT Servomechanisms Laboratory in 1958, and was later standardized by the Electronic Industry Alliance. Computer-aided design (CAD) emerged during the ’60s to give designers the opportunity to visualize their creations before a physical prototype was available. For more info about this go to Tormach’s blog to get a bit of history on CNC. Click on the picture below to go to the article as well.

After reading the article, copy and paste the questions below into a google doc, an LMS, or a Word doc, and hand them in to your instructor.

- What does CNC stand for?

- Around what time did CNC first become popular?

- Where was G code first developed for use with milling machines?

- What are some advantages of CNC over manual machining?

- Going Beyond: What is the difference between a CNC Lathe and a CNC Mill? Find a picture of each on the internet, paste them into the document here, and explain in your own words.

Step 2: An Introduction to G-code and CNC Programming Read an article and answer the questions

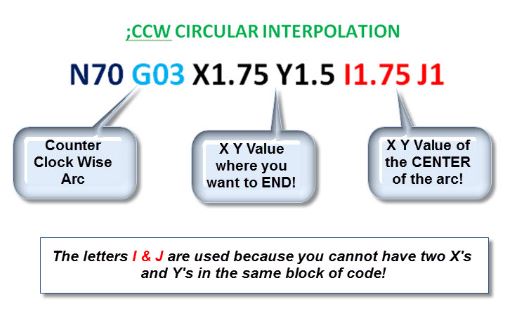

So to make CNC machines work for your CNC plasma cutting projects, you have to be able to communicate with them. The method by which we do this is called G Code. G-code is the operational language for CNC machining. It tells numerically controlled lathes and machining centers how to move tools in order to perform various cutting operations. It is equivalent to manual programming where each operation is spelled out line-by-line and is separate from M-code and T-code, codes that control the machine and tooling. G-code fits somewhere between conversational control, where the operator describes the part and how it should be machined, and CAM, or computer-aided manufacturing, programs, where software develops the necessary toolpaths, feed rates, and so on needed for the CNC machine to cut the material into the finished part. Click on the link below to read the article about how G code programming for CNC machines is done then answer the questions! https://www.thomasnet.com/articles/custom-manufacturing-fabricating/introduction-gcode/

After reading the article, copy and paste the questions below into a google doc, an LMS, or a Word doc, and hand them in to your instructor.

- What coordinate system does a CNC machine use? Where have you heard of this before?

- What does the “G” in G code signify? Be sure to give an example.

- What does the “M” in M code stand for? Be sure to give an example.

- Approximately how many G codes are there when programming a CNC machine?

- Going beyond: Find the link in the article where you would find a list of common G codes, click on it and make a chart that tells what the following G codes do: G00, G01, G02, G03, G20, G21, G54, and G73

Step 3: What are G codes and how do they work? Watch a video and answer the questions

Watch the video above then copy and paste the questions below into a google doc, an LMS, or a Word doc, and hand them in to your teacher.

- What type of CNC machine is that behind Mark in the video? Why did you choose that answer?

- Who was the first person to mount a motor onto a hand wheel of a lathe or milling machine, and what type of motor was it? Be sure to answer both questions.

- What do M codes do, simply put? Be sure to give an example.

- What are DHT Codes?

- What are Feeds & Speeds?

- Why are there G code groups? Give an example in your answer.

- In Mark’s example of a drilling operation, what tool number did he use, and what was the spindle speed in RPM’s?

- What was the Programmed Feed rate in Inches per minute (IPM)?

Step 4: Going Beyond

Going beyond: Using your incredible internet search capabilities and what you have just learned, answer the following three questions. Just copy and paste the questions below into a google doc, an LMS, or a Word doc, and hand them in to your teacher:

Hint: Start at about 4:00 of the video from step 4!

- What code would Mark use if he wanted to use inches in his program, and not the metric system?

- What does an M06 do in Mark’s program?

- What does M03 S2500 mean in Mark’s program?

7,699 total views, 6 views today